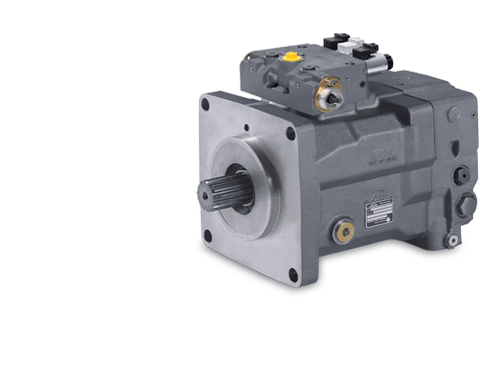

Tomas from Lifco here with another troubleshooting, this time with a Rexroth triple tandem pump. The question I have: what is going on with this stripped shaft? I talked to Fraser and got his insight.

VIDEO LINK: Rexroth Triple Tandem Troubleshooting

Tomas: On our recent Rexroth video (linked above), The customer assumed the shaft was over-torqued. Why do you disagree?

Fraser: Customer thought it was overtorqued. But when that happens it looks like the shaft was sheared into two pieces. It is severe and very sudden. This shaft was worn down and it continued to work until it was almost like a straight (non-splined) shaft. Because there was very little spline material remaining and it continued to work, I assumed that the torque forces on the shaft were not that great.

Tomas: So the torque control being set wrong wouldn’t be the cause?

Fraser: The effects of an improperly set torque control would be the diesel engine stalling. The effects of an overtorqued shaft (meaning the material can't hold on) would've be instant and catastrophic. In this case it was a slow continuous process and only on the material making contact with female coupler.

Tomas: In the video you mentioned ‘shaft engagement.’ What did you mean—and were you right?

Fraser: I was actually wrong. One of my concerns was that the input shaft was only being 75% used. You can see there is a portion that is untouched. When we took it apart, there is a coupler between the two pumps and it had the same 75% engagement. So I said "Oh that means the front coupler (which was not shown because the customer did not send it with the unit) must be fine." But I was wrong, the rear pump is de-rated. This means it can’t handle the same amount of torque as the front pump. I have since learned: the input shaft is supposed to have 100% coupler engagement. So immediately upon seeing only part of the splines worn out on the input, we should know that the shaft connection is not ideal.

Tomas: Could this just be a lubrication or grease issue?

Fraser: They need a complete review of how the torque is getting from the diesel engine to the pump. They likely have a couple problems. Grease, alignment, worn out components, not getting installed corrected. Could be a number of things. Usually if a problem is hard to diagnose then it is because there are a number of issues.

Tomas: So nothing more we could’ve done without having their whole system in front of us?

Fraser: Normally the customer gives us their hydraulic components, and we simply say ‘Yes these were contributing to the problem’ or ‘No these are operating fine but you have something else going on’. But because we posted it on YouTube, our commenters pointed out that a lot of these diesel engines have a spring loaded flywheel, and sometimes they are also filled with oil. The spring loaded flywheel absorbed the diesel engine pulsations. Good teamwork, and it allows us to get some better answers to customers without costing a penny

Tomas: Gotcha, looks like I have some more research to do (I need to look up spring loaded flywheel now!). Thanks for the answers.